Introduction

The Heptanoic Acid Manufacturing Plant Project Report is a comprehensive document that outlines the processes, market analysis, raw materials, financial considerations, and regulatory frameworks involved in establishing a manufacturing facility for heptanoic acid. Heptanoic acid, also known as enanthic acid, is a medium-chain fatty acid widely used in various industrial applications, including the production of flavoring agents, lubricants, plasticizers, and pharmaceuticals. This report will explore the production process, demand for heptanoic acid in key industries, and key aspects to consider when establishing a manufacturing plant for this versatile chemical compound.

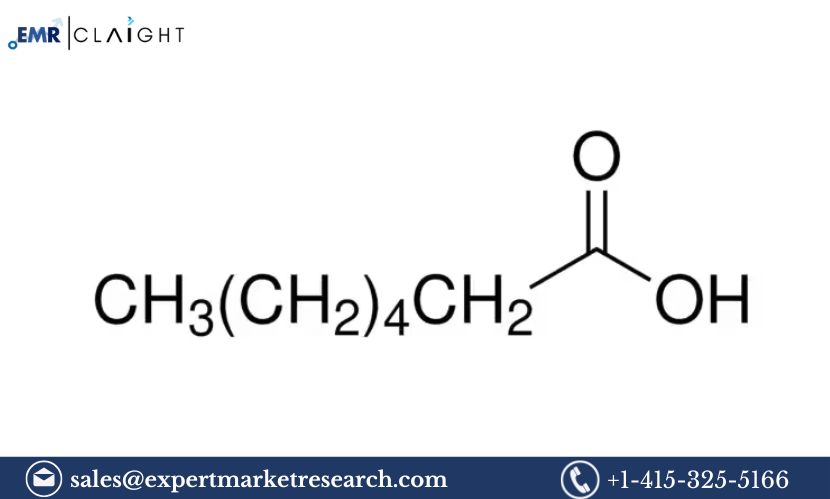

What is Heptanoic Acid?

Heptanoic acid (C7H14O2) is a saturated fatty acid that contains a seven-carbon chain with a carboxyl group (-COOH) at one end. It is typically obtained from natural sources, including animal fats and vegetable oils, or can be synthetically produced via chemical processes. Heptanoic acid has a characteristic pungent, rancid odor and is used in small quantities in many applications. In its various forms, it is known for its use as a flavor enhancer, in manufacturing plasticizers, and as an intermediate in the production of other chemicals.

Due to its chemical structure, heptanoic acid can be used in several important industries, including food and beverages, pharmaceuticals, automotive, and cosmetics. It is a vital ingredient for applications in which its unique properties, such as its solvent capabilities and fatty acid content, are required.

Get a Free Sample Report with Table of Contents@

Market Demand and Applications

The demand for heptanoic acid has been rising across various industries, primarily due to its diverse range of applications. Some of the key sectors driving this demand include:

1. Food and Beverage Industry

Heptanoic acid is used in the food and beverage industry as a flavoring agent. It is primarily used for its fruity, pineapple-like aroma and is found in flavorings for products such as fruit juices, candies, baked goods, and alcoholic beverages. The growing demand for natural flavoring agents in the food industry is expected to boost the consumption of heptanoic acid.

2. Pharmaceutical Industry

Heptanoic acid plays a significant role in the pharmaceutical industry as a key intermediate in the synthesis of active pharmaceutical ingredients (APIs) and other related compounds. Its derivatives are also used in drug formulations and in the preparation of compounds that affect metabolic processes. Heptanoic acid is particularly valuable in producing certain lipids and medications that require a fatty acid component.

3. Cosmetics and Personal Care

In the cosmetics and personal care industry, heptanoic acid is used in the formulation of lotions, creams, and deodorants due to its emulsifying properties. It is also used in skin-care products for its moisturizing effects. The growth of the global skincare market is expected to increase the demand for heptanoic acid as an ingredient in personal care products.

4. Lubricants and Plasticizers

Heptanoic acid is an essential component in the manufacturing of plasticizers and lubricants, which are crucial for industries such as automotive, machinery, and plastics. Heptanoic acid is used to modify the properties of various polymers, improving their flexibility, durability, and resistance to extreme temperatures. Similarly, its presence in lubricants enhances performance in reducing friction in machinery, which leads to smoother operations.

5. Agriculture

Heptanoic acid has applications in agriculture as well, particularly in the formulation of certain pesticides and as a carrier for agrochemicals. Its ability to act as a solvent and emulsifier makes it an effective vehicle for delivering pesticides and other plant treatment chemicals.

Steps to Set Up a Heptanoic Acid Manufacturing Plant

Establishing a manufacturing facility for heptanoic acid requires a careful approach to several factors, including market research, site selection, plant design, and the implementation of appropriate manufacturing processes. Below is a step-by-step breakdown of the process involved in setting up a heptanoic acid manufacturing plant:

1. Feasibility Study and Market Research

A detailed feasibility study and market research are the first critical steps in setting up the plant. This will include:

- Market Demand Analysis: Analyzing the demand for heptanoic acid in various industries, such as food and beverage, pharmaceuticals, lubricants, and personal care products.

- Competitive Landscape: Evaluating the existing players in the heptanoic acid market, their market share, pricing strategies, and distribution networks.

- Regulatory Environment: Understanding the regulations governing the production of heptanoic acid, including environmental standards, safety regulations, and industry-specific guidelines.

- Cost and Revenue Forecasting: Calculating the capital investment, operational costs, and projected revenue to ensure the financial feasibility of the project.

2. Location Selection

Selecting the right location for the manufacturing plant is crucial for minimizing costs and optimizing supply chain efficiency. Important factors to consider include:

- Proximity to Raw Materials: Heptanoic acid is primarily derived from fatty acids or through chemical processes, so locating the plant near suppliers of raw materials like oils, animal fats, and chemical compounds will help reduce transportation costs.

- Transportation and Infrastructure: Access to major transportation routes, including highways, railways, and ports, is essential for the timely delivery of raw materials and distribution of finished products.

- Utility Availability: Reliable access to utilities such as water, electricity, and natural gas is required for continuous production.

- Labor Availability: Availability of skilled labor in the chemical manufacturing sector should be considered when choosing a location.

3. Raw Materials and Equipment

The main raw materials used in the production of heptanoic acid are fatty acids, often derived from natural sources such as vegetable oils or animal fats. For synthetic production, chemical intermediates such as heptanal or 1-hexanol can be used. The equipment required for manufacturing heptanoic acid includes:

- Reaction Vessels: Reactors are needed for the conversion of raw materials into heptanoic acid through processes like esterification or hydrolysis.

- Distillation Columns: These are essential for separating the heptanoic acid from other by-products and impurities.

- Heat Exchangers: These are used to control the temperature of the reaction and ensure efficient heat management during production.

- Storage Tanks: Tanks are required to store both raw materials and finished products.

- Filtration Systems: Filtration units are necessary for removing impurities and ensuring the purity of the heptanoic acid.

- Packaging Systems: Automated packaging equipment is used to package the final product for distribution.

4. Production Process

The production of heptanoic acid typically follows one of the two methods: synthetic production or extraction from natural sources.

Synthetic Production:

- Synthesis from Fatty Alcohols or Aldehydes: In this method, fatty alcohols or aldehydes (such as heptanal) undergo a catalytic oxidation or esterification reaction, resulting in the formation of heptanoic acid.

- Hydrolysis of Fatty Esters: Another method is the hydrolysis of fatty esters, where ester compounds react with water under controlled conditions to produce heptanoic acid.

Extraction from Natural Sources:

- Extraction from Vegetable Oils or Animal Fats: Heptanoic acid can be extracted from vegetable oils or animal fats by hydrolyzing triglycerides under high heat and pressure.

- Purification: The crude heptanoic acid produced through these methods is purified through distillation or other separation techniques to remove contaminants and by-products.

5. Plant Design and Layout

The design and layout of the plant should prioritize efficient workflow, safety, and compliance with environmental regulations. Key considerations for plant design include:

- Safety Systems: Implement safety measures such as pressure relief systems, emergency shut-down procedures, and personal protective equipment (PPE) for workers.

- Waste Management: Design the plant to handle and dispose of chemical by-products and waste materials in compliance with environmental regulations.

- Quality Control: Dedicated quality control labs should be established to test the purity and consistency of the heptanoic acid produced.

6. Workforce and Skill Requirements

Operating a heptanoic acid manufacturing plant requires a skilled workforce with expertise in chemical engineering, plant operations, and quality control. Key positions include:

- Chemical Engineers: To oversee the production process and optimize reactions.

- Production Operators: To manage the day-to-day operation of the manufacturing process.

- Quality Control Technicians: To ensure the product meets industry standards.

- Safety Officers: To implement safety protocols and ensure compliance with health and safety regulations.

7. Regulatory Compliance and Certifications

Manufacturing heptanoic acid involves compliance with a variety of local and international regulations, including:

- Environmental Regulations: Compliance with air and water quality standards to minimize environmental impact.

- Safety Standards: Adherence to occupational health and safety regulations to protect workers.

- Product Certifications: Obtaining certifications such as ISO 9001 for quality management and ISO 14001 for environmental management systems can improve the plant’s reputation and meet customer expectations.

8. Packaging and Distribution

Once produced, heptanoic acid needs to be packaged in suitable containers such as drums, cans, or bottles. Packaging should ensure the product remains secure and uncontaminated. Distribution networks should be set up to supply key markets in the food, pharmaceutical, and industrial sectors.

9. Financial Considerations

Setting up a heptanoic acid manufacturing plant requires a significant financial investment. Key financial considerations include:

- Capital Investment: Investment in land, plant construction, machinery, and raw materials.

- Operational Costs: Ongoing expenses such as labor, utilities, raw materials, maintenance, and waste management.

- Revenue Projections: Based on production capacity, pricing, and market demand, businesses should estimate the potential revenue and profitability of the plant.

FAQs

1. What is heptanoic acid used for?

Heptanoic acid is used in the food and beverage industry as a flavoring agent, in pharmaceuticals as an intermediate, and in manufacturing lubricants, plasticizers, and personal care products.

2. How is heptanoic acid produced?

Heptanoic acid can be produced through the hydrolysis of fatty esters or by synthesizing it from fatty alcohols or aldehydes through catalytic reactions.

3. What are the raw materials required for heptanoic acid production?

The primary raw materials include fatty alcohols, aldehydes (such as heptanal), vegetable oils, and animal fats.

4. Is heptanoic acid environmentally friendly?

While heptanoic acid itself is not harmful, its production process should comply with environmental regulations to minimize waste and emissions.

5. What are the key industries for heptanoic acid consumption?

Heptanoic acid is mainly consumed in the food and beverage industry, pharmaceuticals, cosmetics, automotive (lubricants), and agriculture.

Related Reports

https://www.expertmarketresearch.com.au/reports/australia-personal-loan-market

https://www.expertmarketresearch.com.au/reports/australia-plastic-packaging-market

https://www.expertmarketresearch.com.au/reports/australia-recruitment-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

Leave a Reply