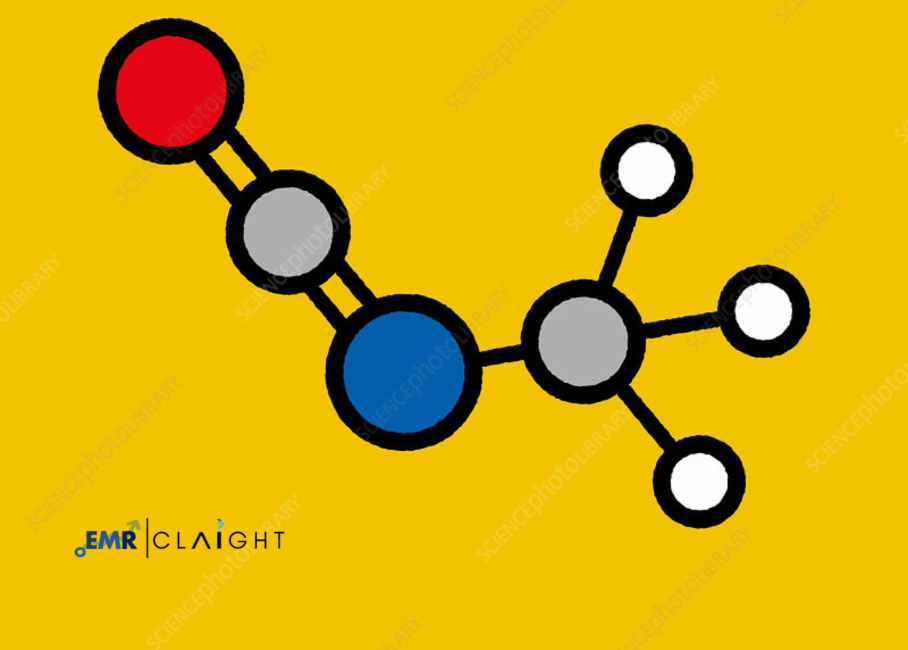

Methyl isocyanate (MIC) is a highly reactive and versatile organic compound widely used in the production of pesticides, herbicides, and other chemical intermediates. Its applications in the agrochemical and chemical industries highlight its significance in manufacturing processes. Due to its reactive nature, the establishment of a Methyl Isocyanate Manufacturing Plant Project requires a well-planned approach, incorporating stringent safety measures, advanced technology, and compliance with environmental and industry regulations to ensure operational efficiency and safety.

Applications and Market Demand

Methyl isocyanate is primarily used in the agrochemical industry for the synthesis of carbamate pesticides and herbicides. Its effectiveness as a chemical intermediate makes it an essential compound in the production of a wide range of agricultural products. In addition to its role in agrochemicals, MIC serves as a precursor in the manufacture of polyurethane foams and plastics. The growing demand for high-yield agricultural solutions and advanced materials has significantly boosted the market for methyl isocyanate, creating lucrative opportunities for manufacturers.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/methyl-isocyanate-manufacturing-plant-project-report/requestsample

Key Steps in Setting Up a Methyl Isocyanate Manufacturing Plant

- Market Research and Feasibility Study Conducting comprehensive market research is critical to understanding the demand for methyl isocyanate and its applications. A feasibility study evaluates the project’s viability by analysing production costs, potential market challenges, and regulatory requirements. This research ensures the plant’s alignment with industry needs and customer expectations.

- Business Plan Development A detailed business plan outlines the project’s objectives, production targets, financial estimates, and marketing strategies. It serves as a roadmap for the plant’s establishment, ensuring efficient resource allocation and operational success. The plan also identifies potential risks and outlines mitigation strategies.

- Location Selection and Infrastructure Choosing an appropriate location is vital for the plant’s operational efficiency. Proximity to raw material suppliers, transportation networks, and utilities like electricity and water should be considered. The infrastructure must include production units, storage facilities, safety systems, and administrative offices. Compliance with zoning laws and environmental regulations is essential to secure operational permits.

- Procurement of Equipment and Machinery Manufacturing methyl isocyanate requires specialised equipment such as reactors, distillation units, and safety systems to handle its reactivity. Investing in advanced technology ensures efficient production and adherence to safety protocols. Collaborating with reliable equipment suppliers for installation and maintenance support is crucial for long-term success.

- Raw Material Sourcing The production of methyl isocyanate involves sourcing high-quality raw materials such as methylamine and phosgene. Establishing a reliable supply chain ensures a steady flow of inputs and uninterrupted production. The quality of raw materials directly affects the efficiency and safety of the manufacturing process.

Manufacturing Process Overview

The production of methyl isocyanate involves several critical stages, each requiring precision and strict safety protocols:

- Raw Material Preparation: The raw materials are inspected and prepared to meet quality standards.

- Chemical Reaction: The raw materials undergo controlled chemical reactions under specific conditions to produce methyl isocyanate.

- Purification: The compound is purified to remove impurities and achieve the desired level of purity.

- Storage and Handling: The final product is stored in specialised containers designed to handle its reactivity.

- Packaging and Distribution: The methyl isocyanate is packaged and transported under strict safety measures to its intended destinations.

Quality Control Measures

Ensuring consistent quality and safety is essential in methyl isocyanate manufacturing. Quality control measures include:

- Raw Material Testing: Verifying the purity and quality of input materials.

- Process Monitoring: Conducting regular checks during production to maintain consistency and efficiency.

- Final Product Testing: Ensuring that the finished product meets industry standards for purity and stability.

Adherence to regulatory standards and certifications enhances product reliability and builds customer trust.

Safety and Environmental Considerations

Given the hazardous nature of methyl isocyanate, implementing robust safety and environmental measures is crucial. These include:

- Safety Systems: Installing advanced safety systems to monitor and control potential leaks or incidents.

- Training: Providing comprehensive training for workers to handle the compound safely.

- Waste Management: Adopting eco-friendly waste disposal methods to minimise environmental impact.

- Emergency Response Plans: Developing detailed plans to address potential emergencies effectively.

Packaging and Distribution

Effective packaging plays a vital role in preserving the safety and stability of methyl isocyanate during transportation and storage. Packaging materials must meet stringent safety standards to prevent leaks and contamination. Clear labelling with hazard warnings and handling instructions is essential. A robust distribution network ensures timely delivery to customers in domestic and international markets.

Sustainability in Manufacturing

Sustainability is a growing priority in the chemical manufacturing sector. Implementing energy-efficient technologies, recycling by-products, and minimising waste help reduce the environmental footprint of methyl isocyanate production. Collaborating with regulatory bodies to adopt sustainable practices further enhances the plant’s reputation and compliance.

Emerging Trends and Opportunities

The methyl isocyanate market is evolving with advancements in technology and increasing demand for agrochemical solutions. The development of safer and more efficient production methods presents new opportunities for manufacturers. Additionally, the rising focus on sustainable agriculture and eco-friendly products drives innovation in the use of MIC-based compounds. Staying informed about industry trends and investing in research and development ensures competitiveness and long-term growth.

Challenges in the Industry

Establishing a methyl isocyanate manufacturing plant involves challenges such as stringent regulatory requirements, high safety risks, and fluctuating raw material costs. Addressing these challenges requires strategic planning, efficient resource management, and continuous innovation. Collaborating with industry experts and leveraging advanced technologies helps mitigate risks and achieve operational excellence.

Leave a Reply