In various industries, materials that can withstand corrosion and extreme conditions are essential for ensuring the longevity and reliability of equipment. One such material that stands out for its excellent resistance to corrosion and high-performance characteristics is Nickel 200 Round Bar. This versatile material, made from a pure nickel alloy, is widely used in industries ranging from chemical processing to aerospace. In this blog, we will explore the unique benefits of Nickel 200 Round Bar, its applications, and why it is often considered the ideal choice for corrosion-resistant applications.

What Is Nickel 200 Round Bar?

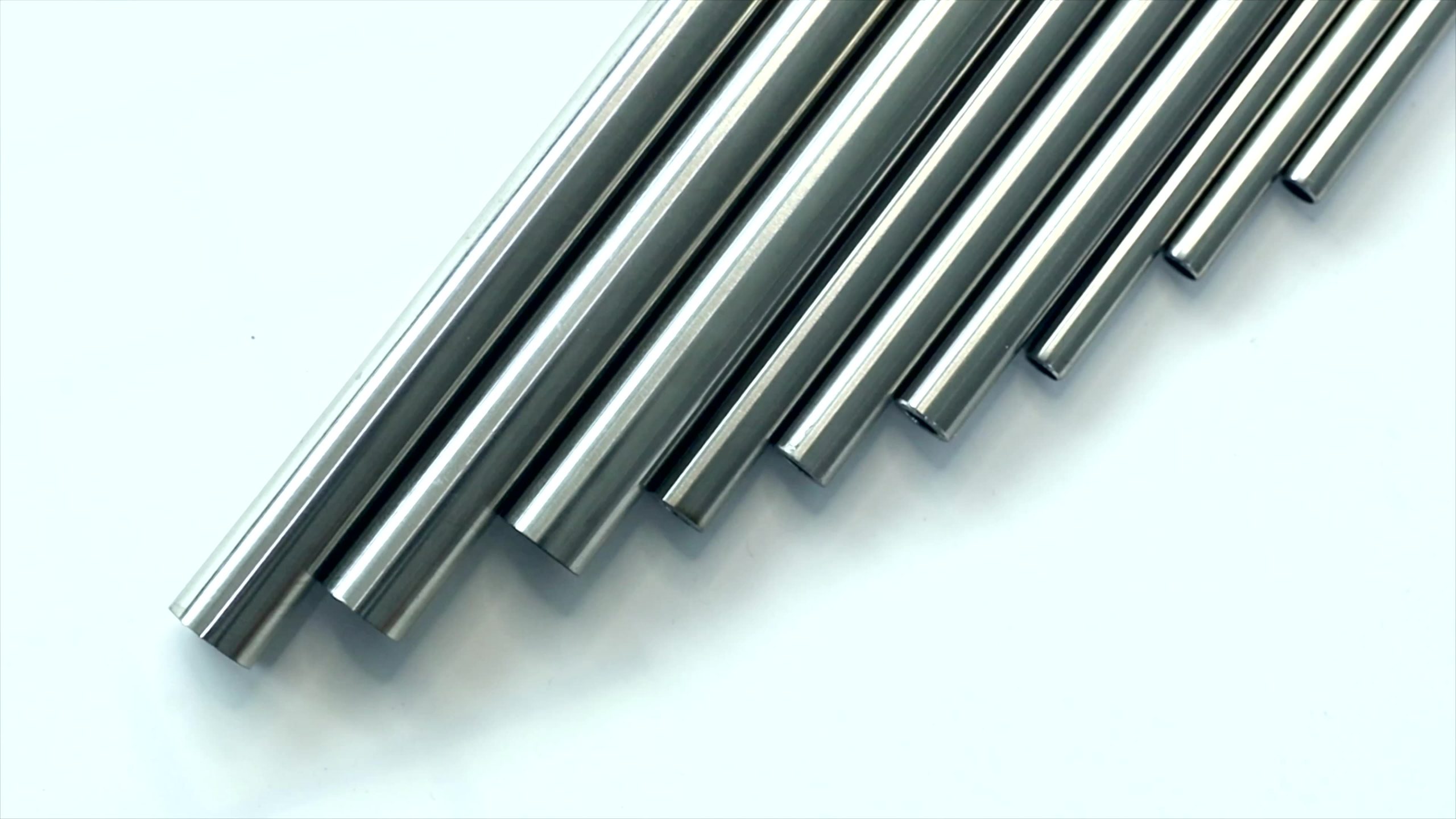

Nickel 200 is a commercially pure nickel alloy, containing at least 99% nickel, with small amounts of iron and other elements. The round bars made from this alloy are highly valued for their superior corrosion resistance, excellent mechanical properties, and versatility. Nickel 200 Round Bars are widely used in environments where resistance to corrosive substances like acids, alkalis, and salts is critical.

These bars are typically manufactured using advanced techniques to ensure they maintain their properties over time. They can be produced in a range of sizes, making them adaptable for different industrial uses. Whether it’s for creating pipes, structural components, or other critical parts, Nickel 200 Round Bars provide the strength and durability required for a variety of applications.

Key Benefits of Nickel 200 Round Bar

-

Outstanding Corrosion Resistance: One of the main reasons for the popularity of Nickel 200 Round Bars is their exceptional resistance to corrosion, especially in alkaline environments. Nickel 200 is highly resistant to a range of corrosive agents, including acids, alkalis, and salts, making it perfect for applications in chemical processing plants, marine environments, and even food processing industries.

-

High Strength and Durability: Nickel 200 Round Bars are known for their mechanical strength and durability, even in extreme conditions. These bars maintain their strength and integrity in high-stress environments, which is why they are widely used in structural applications where reliability and longevity are essential.

-

Thermal Conductivity: Nickel 200 has good thermal conductivity, which is important for applications that involve heat transfer. This makes the material an excellent choice for heat exchangers, reactors, and other equipment where efficient heat dissipation is crucial.

-

Non-Magnetic Properties: Another advantage of Nickel 200 Round Bars is their non-magnetic nature. This makes them ideal for use in industries that require non-magnetic materials, such as in the manufacture of electrical components and in applications where magnetic interference must be avoided.

-

Weldability and Formability: Nickel 200 is known for its excellent weldability and formability. It can be easily shaped into various forms, making it a versatile material for manufacturing components like pipes, fittings, and structural parts. This ability to be easily welded ensures that it can be used in a wide range of industrial applications without difficulty.

-

Resistant to Stress Corrosion Cracking: Unlike some other alloys, Nickel 200 Round Bars are resistant to stress corrosion cracking, particularly in environments that are prone to tension or vibration. This quality makes the alloy a trusted material in demanding industries like aerospace, petrochemical, and power generation.

Applications of Nickel 200 Round Bar

Nickel 200 Round Bars are used in a wide range of industries due to their unique combination of properties. Some of the most common applications include:

-

Chemical Processing: In chemical plants where equipment comes into contact with corrosive substances, Nickel 200 Round Bars are used to manufacture pipes, fittings, and tanks. Their resistance to alkalis and acids makes them ideal for handling harsh chemicals.

-

Marine Industry: The marine environment is notorious for its high levels of saltwater corrosion. Nickel 200 Round Bars are frequently used in shipbuilding and offshore platforms, where corrosion resistance is essential. They are used in components like propeller shafts, seawater piping, and other vital parts exposed to saltwater.

-

Food Processing: Nickel 200’s resistance to corrosion and its non-toxic nature make it suitable for use in the food processing industry. It is often used in manufacturing equipment like tanks, pipes, and valves that come into direct contact with food and beverages.

-

Aerospace and Aviation: In the aerospace industry, Nickel 200 Round Bars are used in aircraft components and engines where high strength and resistance to corrosion are crucial. Their non-magnetic properties are also beneficial in minimizing interference in sensitive equipment.

-

Electronics: The non-magnetic properties of Nickel 200 also make it ideal for use in electronic applications, particularly in components where magnetic interference could be a concern.

-

Power Generation: Nickel 200 is commonly used in power plants, particularly in components exposed to high temperatures and pressures. Its ability to withstand corrosion and stress cracking makes it suitable for applications like reactor cores, turbines, and heat exchangers.

Why Choose Nickel 200 Round Bar?

The choice to use Nickel 200 Round Bars in various applications comes down to their ability to perform reliably in demanding environments. Here are some key reasons why industries choose Nickel 200 for corrosion-resistant applications:

-

Exceptional Corrosion Resistance: Nickel 200 is highly resistant to corrosion, making it the go-to material for applications where exposure to corrosive substances is common. This ensures long-lasting durability and minimal maintenance requirements.

-

High-Performance in Extreme Conditions: Whether it’s high temperatures, harsh chemicals, or high-pressure environments, Nickel 200 Round Bars maintain their integrity and strength, ensuring the reliability of equipment and structures.

-

Long-Term Value: While Nickel 200 Round Bars might come with a higher initial cost compared to other materials, their longevity and performance in corrosive environments mean fewer repairs, replacements, and operational interruptions, leading to significant cost savings over time.

-

Versatility: The material’s ability to be easily fabricated and welded makes it highly versatile. It can be used in a wide range of applications, from industrial equipment to aerospace components, offering flexibility to meet the needs of various industries.

Nickel 200 Round Bar is an excellent choice for industries requiring materials that can stand up to extreme conditions while providing long-term reliability. Its combination of corrosion resistance, strength, and formability makes it a top choice for applications in chemical processing, marine, aerospace, and many other industries. By choosing Nickel 200, companies can ensure that their equipment and infrastructure will continue to perform well over time, even in the harshest environments.

Leave a Reply