Polypropylene sheets, commonly referred to as PP sheets, have become an increasingly popular choice in numerous industries due to their versatile properties and cost-effectiveness. Made from polypropylene, a thermoplastic polymer, these sheets are characterized by their durability, lightweight nature, and excellent chemical resistance. This Pulkit Plastic Products delves into the extensive applications of PP sheets, examining their benefits, pricing considerations, and factors influencing the polypropylene price.

Understanding PP Sheets and Their Composition

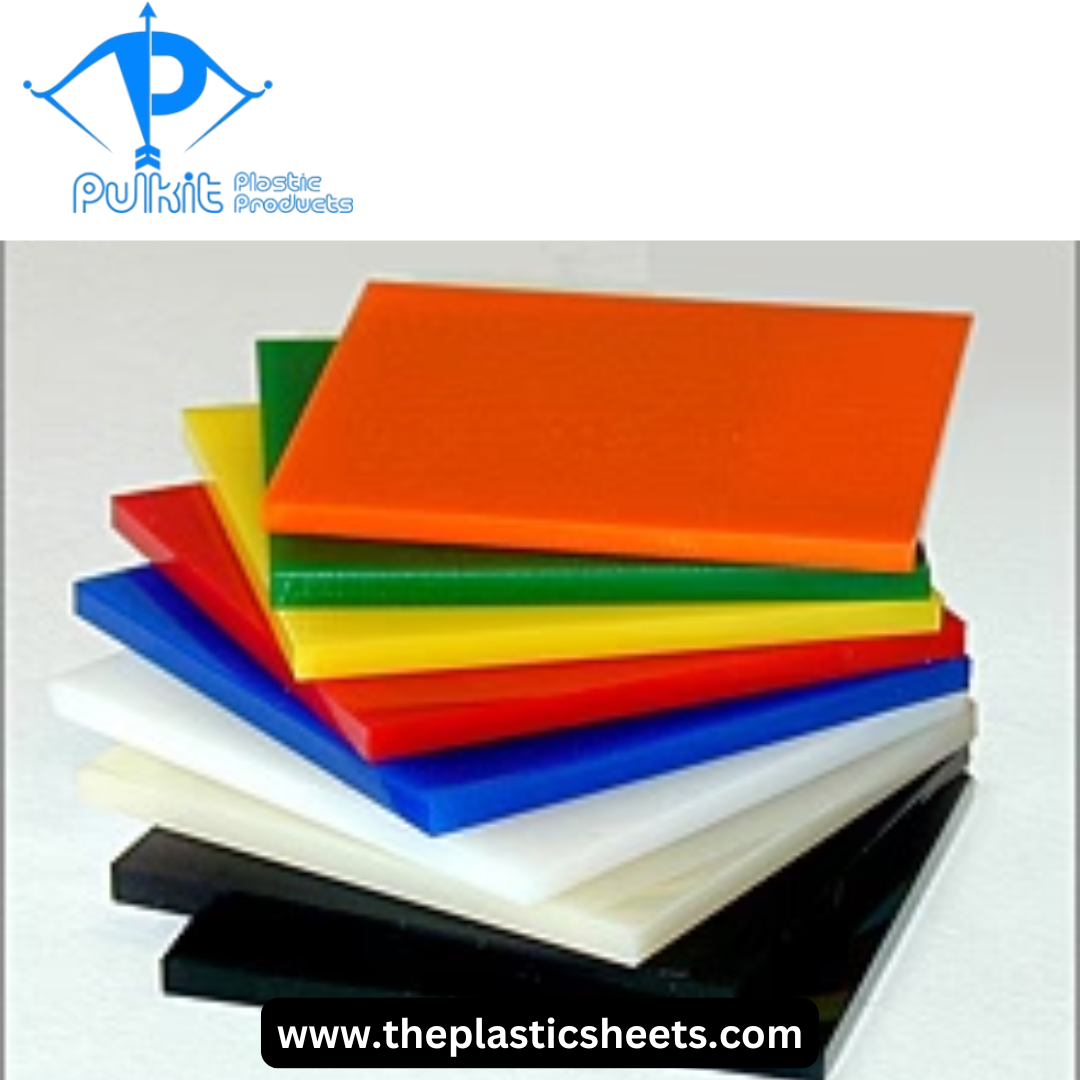

PP sheets are manufactured from polypropylene, a polymer derived from petroleum. The production process involves the polymerization of propylene monomers, which results in sheets that are both lightweight and highly resistant to cracking, breaking, and deforming. The versatility of polypropylene means that PP sheets can be produced in various thicknesses, colors, and finishes, allowing them to cater to diverse applications in different sectors.

One of the key properties of PP sheets is their exceptional chemical resistance. They won’t react with acids, bases, and most solvents, making them ideal for use in environments where chemical exposure is a concern. Additionally, these sheets have a high melting point, enabling them to withstand elevated temperatures without losing integrity. Their lightweight nature allows for easier handling and installation, further contributing to their appeal across various applications.

Furthermore, the non-toxic and recyclable nature of polypropylene makes PP sheets a sustainable choice for environmentally conscious consumers. With a growing emphasis on sustainability, the use of recyclable materials, such as PP sheets, aligns perfectly with green building practices and initiatives aimed at reducing waste in various industries.

Applications of PP Sheets

The wide-ranging applications of Polypropylene price are one of the reasons for their popularity. They are utilized in several industries, including packaging, construction, automotive, and medical sectors. In packaging, for instance, PP sheets are frequently employed to create containers, lids, and other protective packaging solutions. Their lightweight nature and durability make them ideal for shipping and storing a variety of products, ensuring they remain intact during transport.

In the construction industry, PP sheets are often used as wall cladding, insulation panels, or protective barriers. Their resistance to moisture makes them suitable for areas prone to humidity, while their ability to resist UV radiation ensures that they maintain their appearance and structural integrity when exposed to sunlight. Many manufacturers also utilize PP sheets to create custom components or prototypes, taking advantage of their machinability and adaptability.

The medical sector, too, has embraced PP sheets for a myriad of applications, from medical packaging to components used in medical devices. The ability to sterilize PP sheets makes them a safe choice for environments where health and safety are paramount. Across these industries, the innovative capabilities of PP sheets are consistently expanding, showcasing the material’s versatility and importance in modern manufacturing.

Advantages of Using PP Sheets

The benefits that PP sheets offer are numerous and contribute to their growing popularity. One of the most significant advantages is their excellent durability. PP sheets are not only resistant to impacts and scratches but also offer superior longevity in applications where exposure to harsh conditions is expected. This resilience ultimately leads to lower replacement costs and reduced waste, benefiting both businesses and the environment.

Another pivotal advantage is the cost-effectiveness of PP sheets. Compared to other materials like polycarbonate or acrylic, the price for polypropylene is often significantly lower while maintaining similar performance characteristics. This affordability makes PP sheets an attractive option for those seeking high-quality solutions without breaking the bank.

Furthermore, PP sheets are easy to fabricate and can be cut, molded, or welded to meet specific project requirements. This ease of fabrication means that businesses can customize their products without incurring excessive costs or delays in production. Additionally, the lightweight nature of these sheets allows for easier handling during both the manufacturing and installation processes, leading to improved operational efficiency.

Factors Influencing the Price of PP Sheets

Understanding the price of PP sheets is crucial for businesses and consumers alike when making purchasing decisions. The price for polypropylene can vary significantly based on various factors. Primary among these is the thickness and size of the sheets. Thicker sheets often come at a higher price due to the additional material used in their production and their enhanced durability compared to thinner options.

The production method also significantly influences pricing. For instance, sheets manufactured through advanced techniques may be more expensive than those produced using conventional methods. Customization, such as color, texture, or added features, can also drive up costs. Therefore, when evaluating the price of PP sheet options, it is essential to consider whether the additional characteristics align with your specific needs and budget.

Market dynamics, such as supply and demand, play a crucial role in determining the current pricing of polypropylene sheets. Economic changes, fluctuations in raw material costs, and international trade policies can all contribute to price variations. For those looking to invest in PP sheets, keeping an eye on these market trends can help predict future costs and enable more informed purchasing choices.

Finding PP Sheets at Competitive Prices

When seeking to purchase Price of pp sheet, potential buyers should explore various avenues to find competitive prices. Conducting an online search for terminology such as “polypropylene price” or “price for polypropylene” can yield valuable information about local and online suppliers. Many distributors offer bulk buying options which can provide savings for those purchasing in larger quantities.

Local hardware stores and building supply centers often carry PP sheets, offering a hands-on opportunity to examine the material’s quality and thickness before making a purchase. Attending trade shows or conferences that focus on materials science and construction can also provide insight into new products and pricing trends in the market. These events may also offer opportunities to connect with suppliers directly, facilitating negotiations and potential discounts.

Additionally, it can be prudent to establish relationships with manufacturers or wholesalers directly. By developing a vendor relationship, businesses can often benefit from reduced rates, loyalty discounts, or early access to new products. Leveraging resources such as industry networks or associations can further aid in connecting buyers with reliable sources for competitively priced PP sheets.

Environmental Impact of PP Sheets

As the focus on sustainability grows, understanding the environmental impact of materials becomes increasingly important. PP sheets are recognized as environmentally friendly due to their recyclable nature, reducing waste and promoting responsible production practices. Many manufacturers emphasize sustainability in their processes, using recycled materials or implementing efficient strategies that minimize energy consumption and emissions.

In addition to their recyclability, the durability of PP sheets plays an essential role in their overall environmental footprint. Because these sheets can withstand challenging conditions without degrading, they are less likely to need frequent replacement, which contributes to reduced waste generation over time. For businesses and consumers committed to sustainability, opting for PP sheets can align with their environmental goals while ensuring quality and performance.

Moreover, as the demand for eco-friendly materials continues to rise, suppliers are more inclined to innovate and improve their offerings. Many organizations are now developing initiatives to recycle used PP sheets, further closing the loop and enhancing the materials’ sustainability credentials. This ongoing evolution heralds a future where PP sheets can be even more integral to sustainable building practices.

Conclusion

The Price for polypropylene present a compelling combination of durability, versatility, and affordability, making them a favored choice across multiple industries. Their applications span from packaging and construction to medical devices, showcasing their adaptability and performance in challenging environments. While understanding the components that influence the price of PP sheets is essential for informed purchasing, consumers can also look to the environmental benefits of choosing such materials.

As demand for sustainable solutions continues to rise, the role of PP sheets in modern applications is positioned to grow even more significant. With their extensive range of benefits and capabilities, PP sheets provide innovative solutions that meet the needs of today while paving the way for a more sustainable future.

Frequently Asked Questions

Q1: What are the key advantages of using PP sheets in various applications?

A: The key benefits of PP sheets include their excellent durability, chemical resistance, lightweight nature, and cost-effectiveness. Their recyclability also adds to their appeal, particularly for environmentally-conscious consumers.

Q2: How do I find competitive pricing for PP sheets?

A: To find competitive pricing, consider searching for terms like “polypropylene price” or “price for polypropylene” online. Additionally, explore local hardware stores, building suppliers, and online wholesalers for bulk discounts.

Q3: What factors influence the price of PP sheets?

A: The price of PP sheets is influenced by factors such as thickness, size, production methods, and customization. Market conditions, including supply and demand dynamics, can also significantly impact pricing.

Q4: Are PP sheets environmentally friendly?

A: Yes, PP sheets are considered environmentally friendly due to their recyclable nature and durability. Many manufacturers focus on sustainable practices, contributing to reduced waste and promoting responsible production efforts.

Leave a Reply