Polyvinyl Alcohol (PVA) Pulver, commonly referred to as PVA powder, is a synthetic polymer material known for its unique properties and versatility. Derived from polyvinyl acetate through a hydrolysis or alcoholysis process, PVA has become a staple material across industries due to its solubility in water, adhesive qualities, and film-forming abilities. This article explores the properties, applications, production process, and environmental considerations surrounding PVA Pulver.

What is PVA Pulver?

PVA Pulver is the powdered form of Polyvinyl Alcohol, a water-soluble polymer. It is typically available in a fine, granular form, making it easy to transport, store, and handle. This powder dissolves readily in water to create solutions with various concentrations, allowing customization for specific industrial or manufacturing needs.

The composition of PVA Pulver can vary depending on the degree of polymerization and hydrolysis, which influence its solubility, viscosity, and other physical properties. Typically, PVA products are classified as fully hydrolyzed (98-99% hydrolysis) or partially hydrolyzed (87-89% hydrolysis), with each type offering unique functional benefits.

Properties of PVA Pulver

PVA Pulver is valued for its wide range of chemical and physical properties, making it suitable for numerous applications. Key characteristics include:

- Water Solubility

One of PVA’s hallmark features is its ability to dissolve in water. The solubility can be fine-tuned by adjusting the temperature and pH of the water as well as the polymer’s hydrolysis level. - Adhesive and Film-Forming Abilities

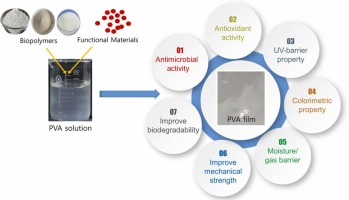

PVA Pulver creates strong, transparent films with excellent tensile strength and flexibility. This makes it ideal for applications where durability and clarity are important. - Biodegradability

PVA is considered environmentally friendly compared to many other synthetic polymers. It exhibits partial biodegradability under specific conditions, which reduces its environmental impact. - Chemical Resistance

PVA demonstrates good resistance to oils, greases, and many solvents, although it is sensitive to strong acids and alkalis. - Thermal Stability

While PVA can withstand moderate heat, it decomposes at elevated temperatures, which limits its application in high-temperature environments. - Barrier Properties

PVA Pulver provides excellent barrier protection against gases like oxygen, making it ideal for food and pharmaceutical packaging.

Applications of PVA Pulver

PVA Pulver is widely used across various industries due to its versatile nature. Some key applications include:

- Adhesives and Binders

PVA is a key ingredient in many adhesive formulations, including glues, tapes, and coatings. Its strong adhesive properties make it ideal for wood, paper, textiles, and ceramics. - Textile Industry

In textiles, PVA Pulver is used as a sizing agent to strengthen yarns during the weaving process. After weaving, the PVA can be easily washed out due to its water solubility. - Paper and Packaging

The polymer’s excellent film-forming and barrier properties make it suitable for food packaging, particularly in applications requiring oxygen or oil resistance. - Construction

In the construction industry, PVA Pulver is utilized as a binder in cement and mortar formulations. It improves the strength, adhesion, and water resistance of these materials. - Pharmaceuticals

PVA is employed in the production of pills and tablets due to its biocompatibility and non-toxic nature. It is also used in the creation of water-soluble films for drug delivery. - Cosmetics and Personal Care

In cosmetic formulations, PVA acts as a film-former and binder, helping create masks, creams, and other personal care products. - 3D Printing

PVA Pulver has recently gained traction in additive manufacturing as a water-soluble support material. It is particularly useful in multi-material 3D printing where temporary support structures need to be removed. - Agriculture

In agriculture, PVA is used to create water-soluble films for seed coatings, fertilizers, and pesticides, ensuring controlled release and reduced waste.

Production Process of PVA Pulver

The production of PVA Pulver involves two primary steps:

- Polymerization of Vinyl Acetate

Vinyl acetate monomers are polymerized to form polyvinyl acetate (PVAc), which serves as the precursor. - Hydrolysis or Alcoholysis

The PVAc is then subjected to a hydrolysis or alcoholysis process, where acetate groups are replaced with hydroxyl groups. This step determines the degree of hydrolysis, a key factor influencing the final properties of the PVA.

Once hydrolyzed, the PVA is dried and milled into a fine powder form, resulting in PVA Pulver.

Environmental Considerations

PVA Pulver is often regarded as an eco-friendly material, but its environmental impact largely depends on the conditions of use and disposal. While PVA is biodegradable in certain environments, such as in wastewater treatment plants, improper disposal can lead to accumulation in natural ecosystems.

Manufacturers are increasingly focusing on developing PVA products with enhanced biodegradability and reduced carbon footprints. Additionally, advancements in recycling and composting processes are being explored to improve the sustainability of PVA-based products.

Benefits of PVA Pulver

The widespread use of PVA Pulver is attributed to its numerous benefits:

- Versatility: It can be tailored for diverse applications, from adhesives to medical products.

- Eco-Friendliness: PVA’s partial biodegradability and water solubility make it a more sustainable choice.

- Cost-Effectiveness: Its widespread availability and ease of use reduce production costs.

- Safety: PVA is non-toxic and safe for use in food packaging and pharmaceuticals.

Conclusion

PVA Pulver is a remarkable material with a broad range of industrial and commercial applications. Its unique combination of water solubility, film-forming abilities, and biodegradability make it an essential polymer in sectors as varied as textiles, pharmaceuticals, and 3D printing. As industries continue to seek sustainable and versatile materials, PVA Pulver is poised to remain a critical component in innovative product development.

Leave a Reply