Polypropylene (PP) fibrillated yarn is one of the most versatile and sought-after materials used in various industries, particularly in geotextiles, agriculture, and packaging. The unique properties of PP Fibrillated Yarn Manufacturers make it an essential component for various types of woven and non-woven fabrics. This article delves deep into the features, uses, and advantages of fibrillated PP yarn, along with a closer look at the role of PP fibrillated yarn manufacturers and fibrillated PP yarn exporters in the global market.

What is PP Fibrillated Yarn?

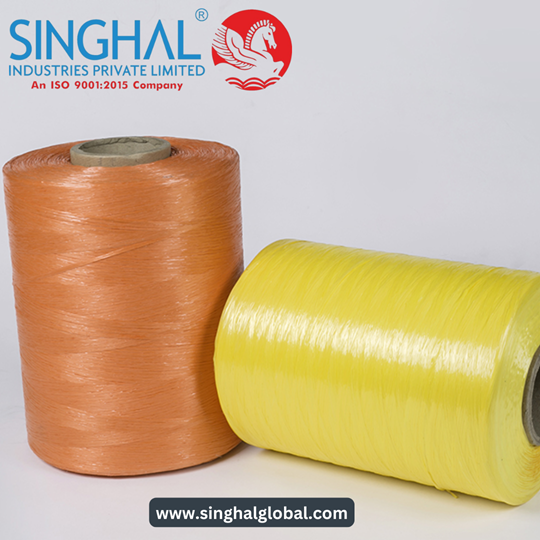

PP fibrillated yarn refers to yarns made from polypropylene fibers that are processed to create fine filaments or fibrils on their surface. These fibrils enhance the yarn’s ability to interlock, which significantly improves the strength and durability of fabrics made from this yarn. Fibrillation is a mechanical process that separates the fibers, resulting in an open and porous structure, ideal for certain applications that require high-strength, flexibility, and resistance.

Polypropylene, being a thermoplastic polymer, is widely used for producing durable and lightweight fabrics. When the polymer is fibrillated, the yarn becomes even more effective at providing excellent tensile strength, water resistance, and durability. This makes PP fibrillated yarn an ideal choice for products like geotextiles, woven fabrics, and reinforced fabrics in various industries.

Properties of PP Fibrillated Yarn

The primary appeal of PP fibrillated yarn lies in its exceptional characteristics, which make it suitable for a wide variety of applications:

- High Strength: The fibrillation process increases the inter-fiber bonding, which enhances the tensile strength of the yarn. This makes fibrillated PP yarn particularly useful for products that need to withstand high levels of stress, like geotextiles used in construction.

- Durability: PP fibrillated yarns are incredibly durable and resistant to degradation, even when exposed to harsh environmental conditions such as moisture, UV rays, and chemicals. This makes it ideal for long-lasting applications.

- Water Resistance: Polypropylene, by its nature, is water-resistant. Fibrillated PP yarn retains this characteristic, making it suitable for use in environments exposed to moisture or in products like drainage fabrics, where water resistance is critical.

- Flexibility: The fibrillated structure enhances the flexibility of the yarn, allowing it to bend and twist without breaking. This is particularly important in applications such as geotextiles, which require flexibility for proper installation and long-term performance.

- Lightweight: Despite its high strength, PP fibrillated yarn remains lightweight, making it easy to handle and use in various applications, from textiles to packaging.

- Chemical Resistance: The yarn’s chemical resistance makes it ideal for use in agricultural applications, where exposure to fertilizers and other chemicals is common. It doesn’t degrade easily when exposed to these substances.

- Environmental Sustainability: Polypropylene is a recyclable material, and fibrillated yarn can be processed into reusable products. This eco-friendly attribute aligns with growing demands for sustainable materials in various industries.

Applications of PP Fibrillated Yarn

One of the key reasons for the widespread use of fibrillated PP yarn is its wide range of applications across different sectors:

1. Geotextiles

One of the most significant applications of fibrillated yarn for geotextiles is in the construction and civil engineering industries. Geotextiles are fabrics used in various construction projects to provide support, drainage, and reinforcement. The unique structure of fibrillated PP yarn makes it ideal for use in these applications. The yarn’s ability to offer high tensile strength, flexibility, and resistance to chemicals makes it a top choice for manufacturing geotextile fabrics used in roads, embankments, dams, and drainage systems.

For example, fibrillated PP yarn is used to produce non-woven geotextile fabrics that help in soil stabilization, erosion control, and water filtration. These fabrics are placed on the soil to prevent erosion while allowing water to flow through without losing soil particles. The durability and water resistance of the fibrillated yarn enhance the overall performance of these geotextiles in harsh environmental conditions.

2. Agricultural Fabrics

In agriculture, Fibrillated PP Yarn Exporters is used to create fabrics that help with soil erosion prevention, water retention, and plant protection. The material’s strength and water resistance make it ideal for producing mulching mats and protective covers for plants. These fabrics help maintain soil moisture, reduce weed growth, and protect crops from the elements, such as heavy rainfall or extreme temperatures.

3. Packaging

PP fibrillated yarn is widely used in the packaging industry for creating woven bags and sacks, such as those used for storing grains, cement, and fertilizers. The yarn’s durability and ability to withstand heavy weights make it ideal for use in 50 kg bags. In addition, its lightweight nature makes it easier to handle and transport compared to other materials.

4. Textiles and Fabrics

Fibrillated PP yarn is also used in textiles and fabrics for clothing, especially for products that require additional strength and resistance to wear and tear. For example, it can be used in the manufacturing of industrial uniforms, outdoor clothing, and other textile products requiring robustness.

5. Road and Construction Fabrics

Another key application of PP fibrillated yarn is in the construction of road surfaces, where geotextile fabrics are used for reinforcement and stabilization. These fabrics help prevent the shifting of soil and promote better load distribution in the construction of roads, highways, and other infrastructure projects.

The Role of PP Fibrillated Yarn Manufacturers and Exporters

As demand for fibrillated yarn for geotextiles and other applications continues to grow, the role of PP fibrillated yarn manufacturers and fibrillated PP yarn exporters becomes increasingly significant. Manufacturers are responsible for producing high-quality yarns that meet the specifications and standards required for different applications, from geotextiles to packaging. These manufacturers use advanced technology and machinery to produce fibrillated yarns that are consistent in quality and offer the desired characteristics for end users.

Exporters play a vital role in ensuring that PP fibrillated yarn reaches international markets. They act as intermediaries between manufacturers and global clients, ensuring timely delivery and compliance with international quality standards. Exporters also help in expanding the reach of PP fibrillated yarn to different regions, promoting its use across diverse industries.

How to Choose the Right PP Fibrillated Yarn Manufacturer

When selecting a PP fibrillated yarn manufacturer, there are several factors to consider:

- Quality Standards: Look for manufacturers who adhere to international quality standards and certifications. High-quality yarn ensures durability and performance in the end product.

- Customization: Some manufacturers offer customization services, such as varying yarn thickness, color, and fibrillation levels, based on the specific needs of the client. This flexibility can be valuable when developing specialized products.

- Pricing: Ensure that the manufacturer offers competitive pricing for fibrillated Fibrillated yarn for geotextiles without compromising on quality. The cost will vary depending on the volume and specific requirements.

- Customer Support: A reliable manufacturer should provide excellent customer service, including post-purchase support, to help clients with any issues related to the yarn’s performance or specifications.

- Delivery Timelines: Timely delivery is crucial, especially in industries like construction and packaging where project timelines are tight. Choose a manufacturer with a reputation for on-time delivery.

Conclusion

PP fibrillated yarn is a versatile and indispensable material used in various industries, particularly in geotextiles, agriculture, and packaging. Its unique properties, such as high strength, durability, water resistance, and flexibility, make it the material of choice for many applications. As demand for fibrillated yarn for geotextiles and other products continues to rise, choosing a reliable PP fibrillated yarn manufacturer or fibrillated PP yarn exporter is crucial for ensuring consistent quality and performance.

Frequently Asked Questions (FAQs)

- What is PP fibrillated yarn used for?

PP fibrillated yarn is primarily used in geotextiles, agricultural fabrics, packaging, and textiles. It is ideal for applications requiring high strength, water resistance, and durability, including soil stabilization, erosion control, and protective agricultural covers.

- How is PP fibrillated yarn different from regular PP yarn?

The key difference between PP fibrillated yarn and regular PP yarn is that the fibrillated yarn undergoes a mechanical process that creates fine filaments or fibrils on its surface. This increases its surface area, strength, and interlocking properties, making it more suitable for applications like geotextiles and packaging.

- Why is PP fibrillated yarn used in geotextiles?

Fibrillated PP yarn is ideal for geotextiles because of its high tensile strength, water resistance, and durability. The interlocking structure of fibrillated yarn enhances the performance of geotextile fabrics, which are used in construction for soil stabilization, erosion control, and drainage.

Leave a Reply